SOLUTIONS ADAPTEDTO TRANSPORTATION OBLIGATIONS

SOLUTIONS ADAPTEDTO TRANSPORTATION OBLIGATIONS

Transportation

As the flow of passengers worldwide increases and the pace of technological development goes faster and faster, material performance expectations are higher and higher. For passengers' security, the materials selected for the construction of modern means of transportation must follow precise legal requirements in terms of flammability and smoke toxicity during ignition. Silicones are directly linked to the lifespan of vehicles as they are naturally resistant to UV rays, ozone, temperature variations, moisture, salt and even some chemical particles.

At STERNE

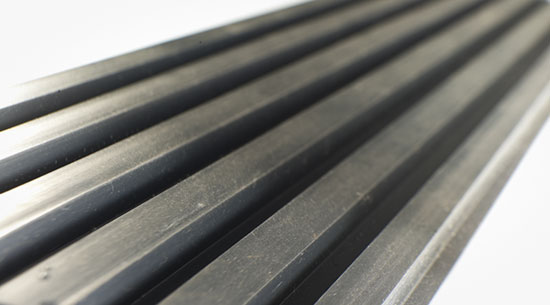

Our materials, either compact silicone or cellular silicone, with density from 200 to 600 kg/m3, meet the normative needs of the transport sector.

We have worked on a complete range of silicone-based, solid and cellular materials: STIRMOTIV ®, which allows us to meet a wide range of needs in the fields of insulation, waterproofing, damping, components...

We have adapted materials to transport sector according to the following standards: NF 16 101 that can reach flame and smoke classifications M1-F0 and M1-F1, in addition to category 1a on the British standard 7 & 8 of BS6853 table, and HL2 R1 and HL3 R22 according to EN 45 545 2 European standard

Characteristics of our materials are : excellent electrical performance and excellent thermal stability, flame resistance, and the release of non-toxic fumes.

Our industrial environment is adapted to the manufacture of silicone products that meet transportation market needs and expectations for rail, aerospace, aviation, aeronautics.

Our manufacturing processes have been established in strict compliance with ISO 9001: 2015 standards, to guarantee the traceability and professionalism of Sterne’s factory.

At Sterne, we are able to adapt ourselves to your needs, both in our manufacturing processes and through the creation of silicone materials that are ideally suited to your applications. Our specialty: the design and development of tailor-made silicone products that meet the new challenges and issues.

Here are some of Sterne’s manufacturing applications :

floating floor silicone supports, windows seals, door seals, protection profiles for luggage racks or overheads, conditioner seals, cut gaskets...

Some of our references :

• The first High Speed Train Line built in South Korea : Luggage racks profile

• The NAT project : Floating floor support

• The Victoria Line – London underground : A whole range of silicone items used for rail train (extruded and molded parts)