AUTOMATION TO ENSUREMASS PRODUCTION

AUTOMATION TO ENSUREMASS PRODUCTION

Automated Production

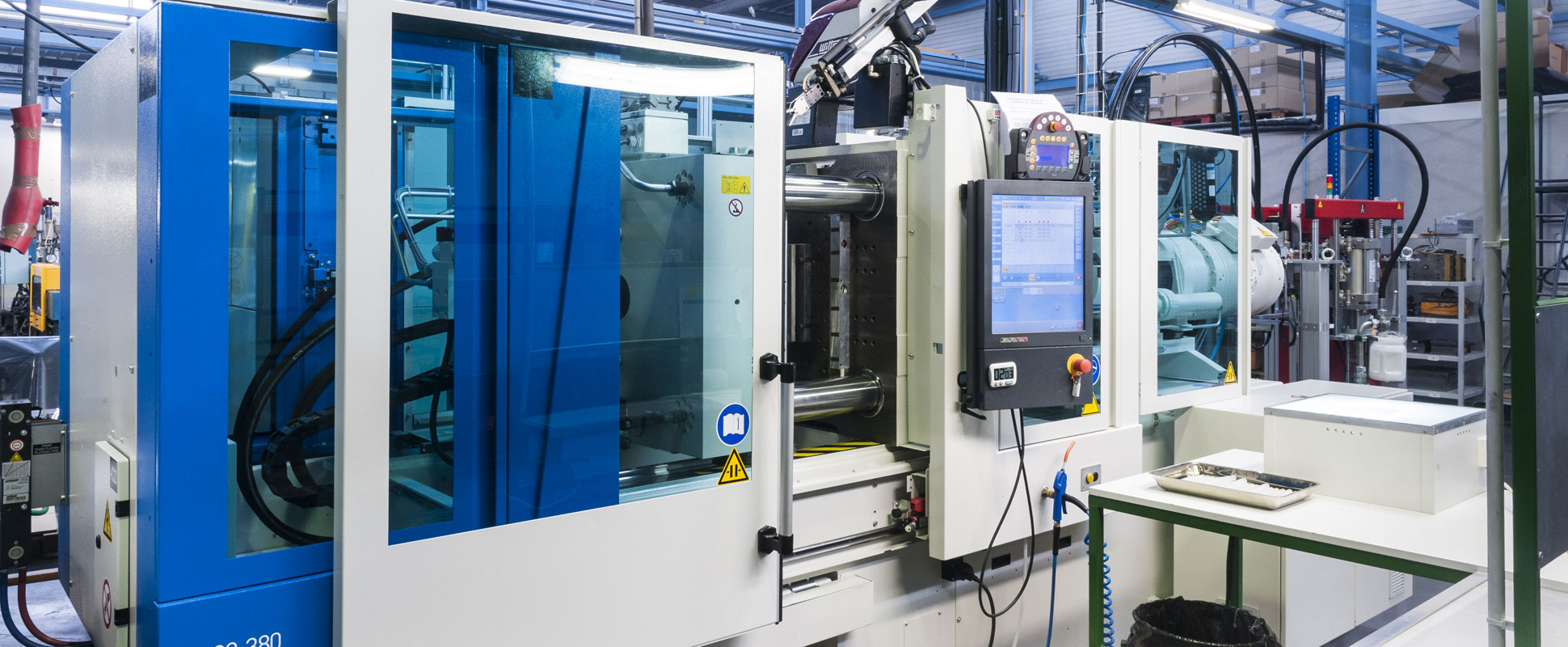

In 2014, Sterne made the strategic choice to invest in LSR processes. Some years later, the company customizes its machines to obtain automated manufacturing processes that meet market needs and customer expectations.

By expanding its machine park and by specializing in LSR injection molding or liquid solution, the Sterne company anticipates new markets. Our automated LSR injection manufacturing method brings a homogeneous and aesthetic finish to the product, in particular thanks to precision dosage and no interference of foreign bodies. The raw material is never handled, but worked in a closed circuit. This LSR injection technology without carrots but with fully mastered automation processes ensures a substantial production volume.

At Sterne, automated manufacturing processes are mastered in different environments, especially in our clean rooms and industrial workshops. With an area of more than 3000 m² dedicated to manufacturing production, we transform silicones in compliance with ISO 9001 : 2015 and ISO 13485 : 2016 standards, a guarantee of quality and product reliability for our customers.

Robotic gripping systems developed internally

Allowing production without human intervention :

With the possibility of 24-hour uninterrupted operation

With quality control under the responsibility of Sterne's employees

Key principles of automation

Behind these automation systems are people: engineers and industrialization managers,... behind these machines there are programs and developers.

The idea is to create a program that creates a dialogue between actors - machines – systems.

Development will consist, in this case, of gripping sequences where movements realized by the automated arm will be transcribed, creating a dialogue between machine and arm. Each machine has its own language, so it is necessary to repeat the operation for each machine where automation is desired.