HEALTHCARE,OUR CORE BUSINESS

HEALTHCARE,OUR CORE BUSINESS

Health

The medical business is constantly facing new challenges that require cutting-edge technology.

New concepts that enhance medical services, find key solutions with silicone. In fact, silicone is a clinically recognized material as it is inert and resistant over time.

At STERNE

We master HCR and LSR silicones manufacturing processes, for medical and biomedical applications.

We own a large range of silicone compounds offering the most advanced technical properties that meet standards such as ISO 10 993 and USP Class VI.

We have a manufacturing environment that is adapted for medical device production: cleanrooms classified from ISO 6 to ISO 8 frameworks.

Our quality system management functions in accordance with ISO 9001 : 2015 and ISO 13485 : 2016 standards,

to comply with medical and biomedical requirements.

With our solid expertise in medical and biomedical fields, which remain our core markets, our flexibility and know-how allow us to offer a wide choice of materials that meet levels of toxicity, cytotoxicity, biocompatibility, for implanting at short or long term criteria,... We adapt our manufacturing capabilities to the specificity of the medical devices, and we accompany each project from its inception to the integral design & conception to production in series.

Examples of manufactured devices :

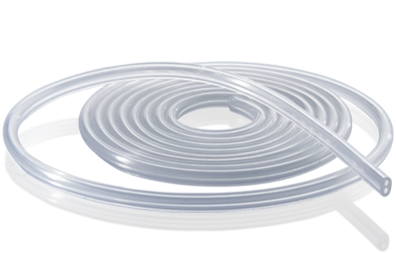

Short term implantable & non implantable appliances: Silicone tubes, drains, silicone mats, suction cups, pressurising pumps and handles ...

As well as implantable medical devices such as septa, implantable chambers, gastric rings, reinforcement implants wall, catheters...

Considering a global context in which the hygiene, pharmacy, para pharmacy and cosmetic industries are steadily growing, Sterne must stay at the edge of technology and continually improve its production chain optimisation while maintaining its high quality level standards.

Silicones remain an ideal material for cosmetic and pharmaceutical applications. Thus, this compound associated with proper manufacturing processes, allows us to meet these markets’ ambitions, precisely and efficiently, especially with regard to: purity, hygiene, biocompatibility and technological development, along with the normative requirements of these markets.

Several examples of applications such as tubes for peristaltic pumps, tubes for fluid transfer, dryer seal, freeze dryer, sterilizer seals, inflatable seals,...

But also silicone products meeting needs for childhood, oral products, mold for cosmetic such as lipstick,...